Lesintor - 20+Years Industry experience, Professional plastic crusher manufacturers

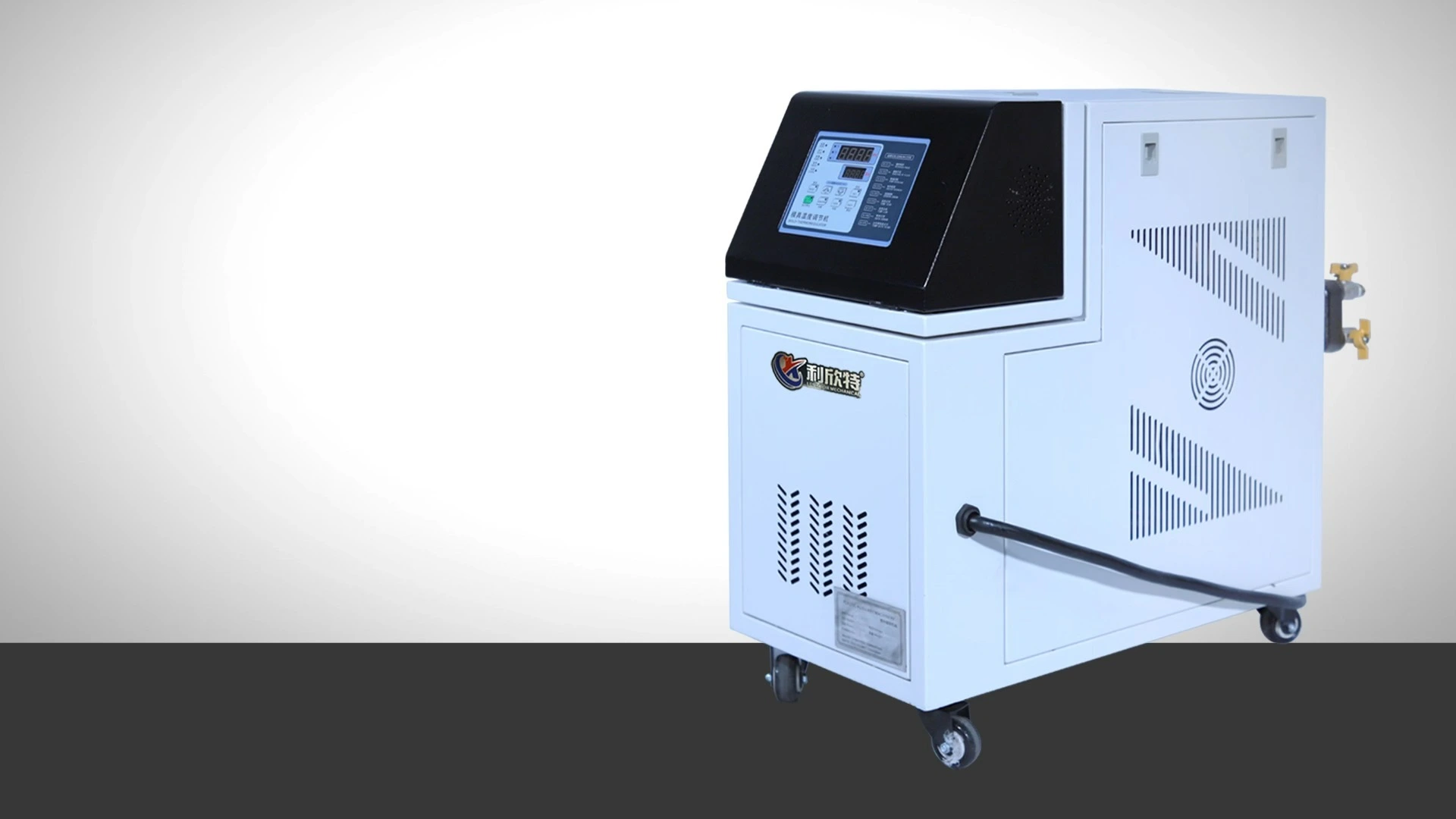

LESINTOR Precision Mold Temperature Control Unit System -Lesintor

The mold temperature controller serves as a vital "temperature manager" in modern industrial automation. By delivering precise, efficient, and stable thermal control to molds/equipment, it enhances product quality, boosts production efficiency, reduces scrap rates, shortens cycles, extends mold life, and cuts energy costs.

Selecting an appropriate controller (water/oil type, temperature range, power, flow rate, accuracy, safety, etc.) is critical for optimizing processes and ensuring economic efficiency.

Technical Parameter

| Model | Coolon gmethod | Medium | Temperature range | Cooling water piping | Total power | Heating power |

Pump power |

Pump lift(M) | Pump flow(L/min) | Dieconnector | Dimension(mm) | Weight(KG) |

| LXT-MTC-W-6KW | Direct cooling | Water | 35-120 (single system) |

1/2 | 6.37KW | 6KW | 0.37 | 27 | 35 | 3/8*4 | 650*270*620 | 44 |

| LXT-MTC-W-9KW | 9.75KW | 9KW | 0.75 | 40 | 45 | 3/8*4 | 650*270*620 | 45 | ||||

| LXT-MTC-W-12KW | 12.75KW | 12KW | 0.75 | 40 | 45 | 3/8*4 | 650*270*620 | 46 | ||||

| LXT-MTC-W-18KW | 19.5KW | 18KW | 1.5 | 40 | 90 | 3/8*4 | 810*370*840 | 90 | ||||

| LXT-MTC-W-24KW | 26.2KW | 12+12KW | 2.2 | 22 | 240 | 3/8*6 | 810*370*840 | 108 | ||||

| LXT-MTC-W-36KW | 38.2KW | 18+18KW | 2.2 | 22 | 240 | 810*370*840 | 112 | |||||

| LXT-MTC-O-6KW | Indirect cooling | Condu ctionoil | 35-180 (single system) |

1/2 | 6.37KW | 6KW | 0.37 | 27 | 35 | 3/8*4 | 650*270*620 | 44 |

| LXT-MTC-O-9KW | 9.75KW | 9KW | 0.75 | 40 | 45 | 3/8*4 | 650*270*620 | 45 | ||||

| LXT-MTC-O-12KW | 12.75KW | 12KW | 0.75 | 40 | 45 | 3/8*4 | 650*270*620 | 46 | ||||

| LXT-MTC-O-18KW | 19.5KW | 18KW | 1.5 | 40 | 90 | 3/8*4 | 810*370*840 | 101 | ||||

| LXT-MTC-O-24KW | 26.2KW | 12+12KW | 2.2 | 22 | 240 | 3/8*6 | 810*370*840 | 114 | ||||

| LXT-MTC-O-36KW | 38.2KW | 18+18KW | 2.2 | 22 | 240 | 810*370*840 | 120 | |||||

| Specifications are subject to change without notice. | ||||||||||||

Features

● With Bangpu control panel, the performance is stable and reliable, and the functions are perfect.

● Isolated electrical control box has good heat insulation effect and extends the service life of electrical appliances.

● Automatic exhaust when starting up, the water type is a stainless steel integrated pipeline, and the heating is even. Reduce pipe resistance and rust.

● Rapid heating and cooling time, stable temperature.

● Seamless tube heating wire, obvious energy saving effect.

● The safety protection and fault indication system is complete, and maintenance is convenient without the need for professionals.

● The water pump horsepower and heating power can be customized according to process requirements, and the electrical appliances are from Deli West high-end series products, cooling water pressure protection function.

Product Details

Main application areas

● Resource Recovery: Primary crushing of waste plastics, waste rubber (especially tires), waste paper, waste metal (pre-treatment), electronic waste (WEEE).

● Waste treatment: Reduction and pre-treatment of bulky household waste (furniture, mattresses), industrial waste, commercial waste.

● Biomass Energy: Crushing of biomass such as wood, branches, straw, etc. for the preparation of fuels (e.g. RDF/SRF) or biogas feedstock.

● Scrap car dismantling: Crushing of car shells, interior parts, non-metallic parts, etc.

● Waste electrical appliances dismantling: crushing refrigerators, washing machines, air conditioning shells, etc.

● Paper industry: waste paper bundles of broken unpacking.

● Confidential Destruction: Secure destruction of documents, hard disk, products (anti-counterfeit destruction).

FAQs

● Oil Type: For high-temperature processes (up to 350°C+). Delivers stable heat transfer for demanding applications.

● Tip: Water is ideal for fast cooling; Oil excels in extreme-heat environments like rubber vulcanization.

● Power (kW) = [Mold Weight (kg) × Specific Heat (kJ/kg·K) × Temperature Delta (°C)] / [Heating Time (s) × Efficiency Factor (0.6-0.8)]

● Example: Heating a 500kg mold from 20°C to 150°C in 600s requires ≈45kW (efficiency factor 0.7).

● Standard molds: 30-70 L/min

● Complex geometries: 80-100 L/min

● Standard models: 380V/3-phase (50/60Hz)

● Custom voltages: 110V/220V/440V supported

● Warning: Voltage fluctuation >±10% may damage heaters!

● Check power supply: Verify circuit breaker and heater resistance.

● Inspect media level: Top up thermal oil/water if low.

● Clear blockages: Clean filters and valves (Isolate pump first!).

● Shut down the unit and check cooling water valves (must be fully open).

● Clean the inlet filter (clogging reduces cooling efficiency by 30%+).

● Contact our 24/7 multilingual support for remote diagnostics.

● 48-hour spare parts delivery from regional warehouses (EU/US/SEA).

● year warranty (5 years for heaters/pumps).